PDMS (Plant

Design Management System) is 3D Design software package developed by AVEVA Group Plc (UK based Information Technology Company). PDMS provides various

functions which are useful for Engineering, Design and Construction of Chemical

Process Plants (both offshore and onshore Projects).

PDMS is Multi-User, Multi-Discipline 3D design tool

which can be customized with PML (Programmable Macro Language) and C# to suit

company or Project Requirements. PDMS Global allows big and complex projects to

be divided over geographical regions/offices on which users can work

concurrently from their respective locations depending upon scope of work

agreed.

PDMS enables you to design 3D interactive computer

model of Chemical Process Plant with full colour shaded representation. PDMS

User selects and positions components from available catalogues. 3D Model becomes source of engineering data for all

sections and disciplines involved in design project.

PDMS clash checking facility ensures clash free

model to be generated to eliminate scope of error that could arise on site

while construction. Reports can be generated from PDMS to perform quality check

in design so unwanted errors could be avoided. 2D engineering drawings which

are produced using PDMS, forms sharing links to transfer information from Design

office to Construction site.

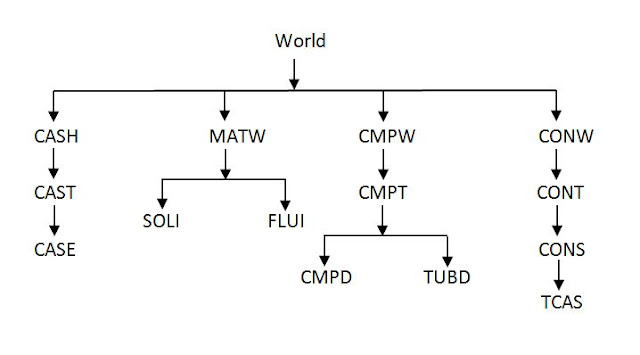

PDMS stores all kind of data in respective Database

depending upon type of data to be stored. Databases are created by

Administrator as per project requirements along with Users who will work on

those databases with required access rights.

PDMS is split into a number of Modules which are

used at different stages in Plant Design Process.

Availability of PDMS Modules differ depending upon

type of license agreement.

In following section, we will discuss about PDMS

Modules and their role/ Functionality in Plant Design Process.

1.

Design Modules

I. DESIGN

Design

is Main constructor Module in which Complete Chemical Process Plant is 3D

modelled. User selects required components from available specifications and

catalogues and positions them as per engineering design. 3D model data is

stored in Design database for individual site created. Design Module provides

facility to check elements for Clashes, Reporting to produce various design

documents for quality checks, Material Takeoff and Preview of Piping

Isometrics.

Design

Module has Applications which provides suitable functions to work on particular

discipline. E.g. Equipment, Piping, Cabling, etc.

II.

SPOOLER

Spooler

is used for pipework spooling. In this Module, Pipework design can be split

into logical sections (i.e. Spools) which are ready fabrication. Spool data created in Spooler module can be

output as Isometric Drawing using ISODRAFT Module.

2. Drafting Modules

I.

DRAFT

In

this Module, Fully dimensioned and annotated 2D drawings of 3D Model are

created. Data required for creation of drawings is accessed through Design

Database while rest of data is stored in Draft database. Like Conventional Engineering

Drawings, User creates views to show particular area of 3D model in required

direction. Dimensions and Labels are attached to design elements which are

stored under respective view.

II.

DIAGRAMS

This

Module is used for creation of P&ID, HVAC and Cabling Diagrams. This

Application uses AVEVA Design Platform GUI and Diagram Layouts are created

using an Embedded Microsoft Office Visio drawing control. Data entered into this application is stored

in Schematic Database.

This

Module uses Diagram, Stencil and Template Path to create Diagram File. User need

to select mode to work to create either P&ID/HVAC/Cabling Diagrams. Diagram

files created in this module can be saved in binary format or XML format.

III.

Schematic Model Manager

Schematic

Model Manager is used to Import P&ID data from XML file into Schematic

Database which can be viewed and Modified if required in later stage of

Project.

3. ISODRAFT

ISODRAFT

is used to produce automatically annotated and dimensioned piping Isometric

drawings along with Material list for that pipe. User need to select from

Option file available for project working on, Option file can be customized to

suit company or project requirements by administrator. ISODRAFT provides option

to take MTO which can be saved to Text file for each Pipe, which can be later used

to generate Bulk MTO for Plant.

4. Catalogues and Specification Management Modules

I. PARAGON

This Module Used for Creation and

Modification of Catalogues which are referenced by Specification reference

of Component. Administrator is directly responsible for

Catalogue Creation, Modification.

Component Catalogue normally

holds information about connection, Physical Shape, Obstruction and Bolting

requirements.

Paragon also stores specification

to be used for project, connection Compatibility information of

Components, Material and Detailed description of components.

Catalogues must be setup properly

in order to avoid any errors in 3D modelling.

II.

SPECON

SPECON

is Specification Constructor Module, which allows administrator to create or

modify specification to suit Project requirement.

III.

PROPCON

PROPCON

is property Constructor Module, administrator create or modify properties

database. Properties database hold information about properties of Component

and materials which may be used for stress analysis, calculation of weights,

Centre of gravity for components.

5. Project Administration Modules

I.

ADMIN

ADMIN

is main administrative module which plays important role in setting up Project,

database creation, User Creation and access rights for Users. Depending Upon

size and complexity of Plant, Plant is divided into individual areas (either on

basis of Physical area or Design Area). It allows administrator to setup fonts, Module

definitions for Project.

ADMIN

module provides important features which are useful for Project Maintenance

such as compacting Database to reduce database size by removing unwanted data, Upgrading PDMS Projects when database

structure changes.

II.

LEXICON

LEXICON

is used to create User defined attributes. Every element in PDMS has set of

attributes which can be set or read. Sometimes default attributes provided by

AVEVA may not sufficient; in that case we may define our own attributes which

can satisfy requirement which are called as User Defined Attributes. UDAs

created in LEXICON are held in Dictionary database. Administrator can choose

type of attribute, scope of attribute (e.g. Pipe, Equipment, etc.) and maximum

value for UDA.

UDAs

are prefixed with Colon (:) and treated in same way as that of default

attributes when extracted to drawings or reports.

III.

MONITOR

MONITOR

module serving as Entry point to PDMS whenever User starts PDMS. This module is

commonly used to query system status, Users, MDB, Databases, Teams, and Modules. Batch

Processing and messaging can be done in MONITOR module.

MONITOR

module can be used to change Project Password. Also, User and MDB can be changed.

If

there is problem in Project which prohibits another PDMS module to load,

Monitor module will be opened automatically.